More Than A Machine

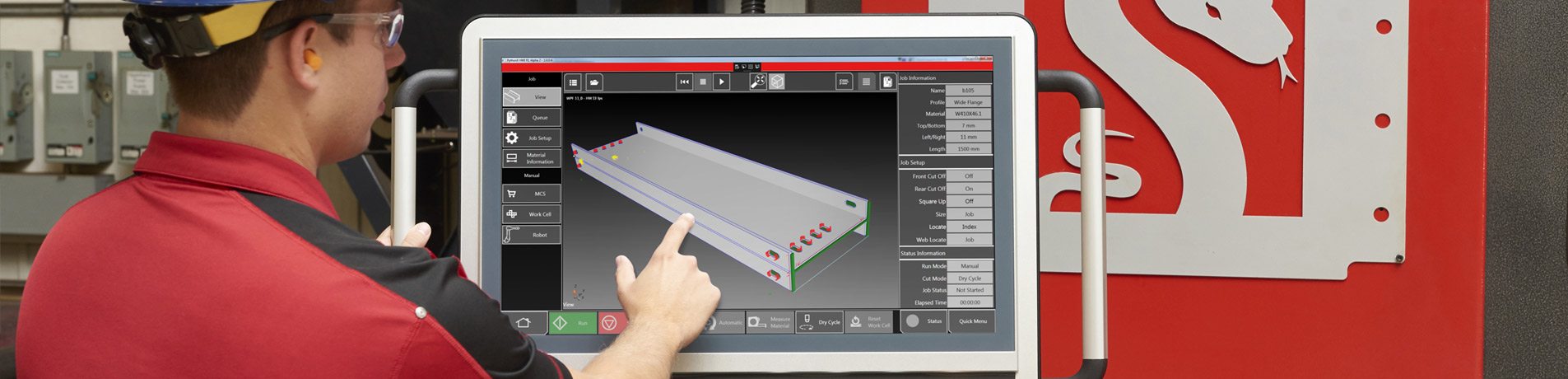

PythonX STRUCTURAL has created a NEW STANDARD in the way you think about running a fabrication shop.

Compared to traditional machines, PythonX STRUCTURAL:

- Uses a fraction of floorspace

- Needs only minutes of processing time

- Requires Only One Operator & No Programming

- Offers complete fabricating capability for a fraction of the price

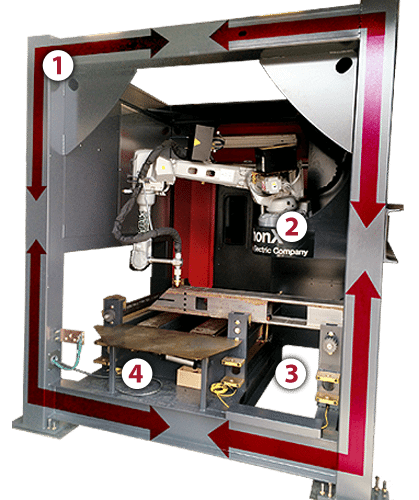

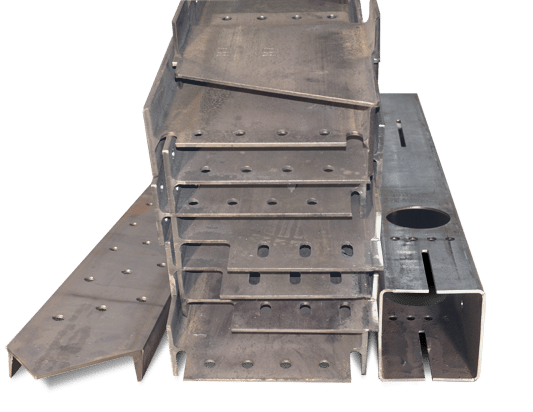

SOLID CONSTRUCTION + UNIQUE CAPABILITIES

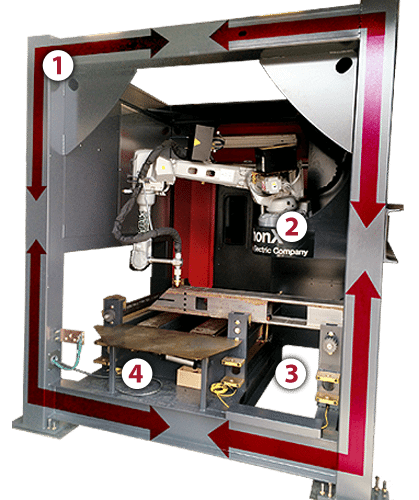

1. ONE PIECE WELDED BOX FRAME

Heavy, strong and designed to be extremely rigid. The uni-body welded frame provides the most stable, vibration free foundation for the cutting system.

2. FIXED STATIONARY ROBOT BASE

A fixed base welded to the box frame lets PythonX STRUCTURAL use only the robot motion to perform cutting – no additional axes of motion to add vibration, backlash or sway that degrade cut quality.

3. UNDERSIDE CUTTING

The underside cuts are performed in a separate zone where no scrap pieces fall and no crash can occur.

4. CUTS AND SEVERS

All sever operations occur in this zone, with ample room for endcuts and scrap to accumulate without having to worry about crashes.

Built For

Maximum

Precision

Heavy, strong and designed to be extremely rigid. The uni-body welded frame provides the most stable, vibration free foundation for the cutting system.

2. FIXED STATIONARY ROBOT BASE

A fixed base welded to the box frame lets PythonX use only the robot motion to perform cutting – no additional axes of motion to add vibration, backlash or sway that degrade cut quality.

3. UNDERSIDE CUTTING

The underside cuts are performed in a separate zone where no scrap pieces fall and no crash can occur.

4. CUTS AND SEVER

All sever operations occur in this zone, with ample room for endcuts and scrap to accumulate without having to worry about crashes.

4-Side Tube Cutting

PythonX STRUCTURAL adds a fixed robotic arm to cut the tube underside and process all 4 sides in one pass. The only robotic plasma to perform 4-side cutting and beveling without mounting the robot on a moving or rotational base, which sacrifices cut quality.

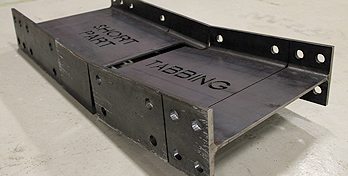

Part Tabbing

Part tabbing allows for shorter structural steel parts to remain attached to the main beam for easier handling and storage. With PythonX STRUCTURAL, the type of tab and tab length is programmable by the operator for the ultimate in flexibility.

Shorter Piece Transfer

For added flexibility, PythonX STRUCTURAL has advanced software combined with closer conveyor roller spacing to allow for short parts to be transferred from the cutting area after a cut to length operation. No need to open or reach into the cutting cabinet.

Larger Work Envelope

The expanded robot cutting area allows for more features to be cut at once. That reduces material indexing, leading to even lower total processing time per piece.

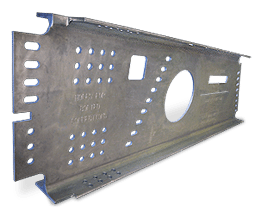

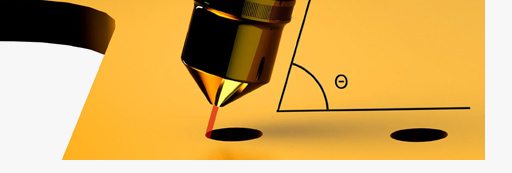

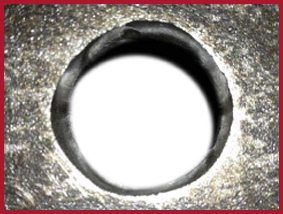

Patented Bolt Hole Process

Only PythonX STRUCTURAL employs a patented process that tilts the torch, instantaneously changes speeds and uses sophisticated software algorithms to produce straight through holes that are NEARLY TAPERLESS.

THE LOWEST COST PRODUCER WINS

Be the Lowest Cost per Ton Producer

But, if you pay about the same as your competitor for steel and labor, how do you get to the lowest cost per ton?

You get LEAN.

PythonX STRUCTURAL is the lean machine that lets you do more with less:

- Less Time per Piece

- Less Material Handling

- Less Inventory

- Less Waiting

- Less Waste

- Less Space

- Less Overhead

- Less Programming

- Less Errors

- Less Scrap

We’ve been able to pass along to our customers the savings of reduced time in the shop, so we’re getting more jobs because we’ve been able to reduce our operating costs.

PythonX instantly automates the growing fabrication shop, providing a level of CNC sophistication that would otherwise take years and millions of dollars to reach with traditional fabrication equipment. Smaller fabrication shops of 10,000 sq. ft. and 10 to 20 employees are now using PythonX as their foundation for growth.

PythonX has made us more competitive. We can take on larger projects having a smaller margin for error. And because errors are costly, it has increased our margins on these types of projects.

MEET THE WINNERS: PYTHONX CUSTOMERS

What PythonX STRUCTURAL Customers Are Saying

We measure our success through the success of our customers around the world. Here's what real-world companies have to say when we asked them about their PythonX STRUCTURAL.[video_lightbox_youtube video_id="m4ty603nf7Q&rel=0" width="720" height="405" anchor="Watch...

FCC Construction – Competitive Edge With 4-Year-Old PythonX

Based in Caledonia, Michigan, FCC Construction Inc. has been in business for over 60 years. Their expertise allows them to manage entire projects from blueprints to ribbon cutting.The Challenge FCC Construction is not your typical structural steel fabricator; they...

Vogue Steel – Becomes a Leader with PythonX

Established in 1992, Vogue Steel is one of the leading structural steel fabricators in the United Arab Emirates. Based in Sharjah, find out how they transitioned from a small fabricator in Abu Dhabi to more than 12 major projects throughout the UAE with the help of...

INDUSTRY LEADING QUALITY AND ACCURACY

Best In Class Cut Quality And Accuracy

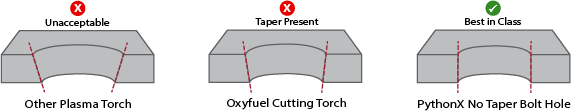

Poor hole quality and cut finish can lead to failed inspections, lost jobs and a damaged reputation. But PythonX pioneered robotic plasma hole technology and has been producing the undisputed best bolt holes and cuts in the industry for many years. PythonX bolt holes have been lab tested and AISC compliant.

Bolt Holes

PythonX automatically tilts the cutting torch and uses a patented cutting process resulting in a perfectly straight through hole that is NEARLY TAPERLESS.

PythonX

Competitor

Slots

PythonX cuts slots and other shapes to the exact specified dimensions allowing for perfect fitup.

PythonX

Competitor

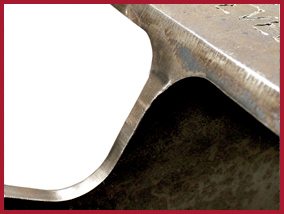

Copes

The PythonX copes are produced with a mirror like finish and a smooth corner radius. No touch-up is required.

PythonX

Competitor

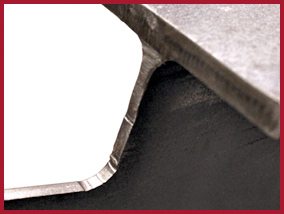

Notches

Notches, cutouts and flush cuts made by PythonX are smooth and do not require additional grinding or shaping. Their perfect fitup also results in less welding.

PythonX

Competitor